CNC Plasma Structural Plate Processing

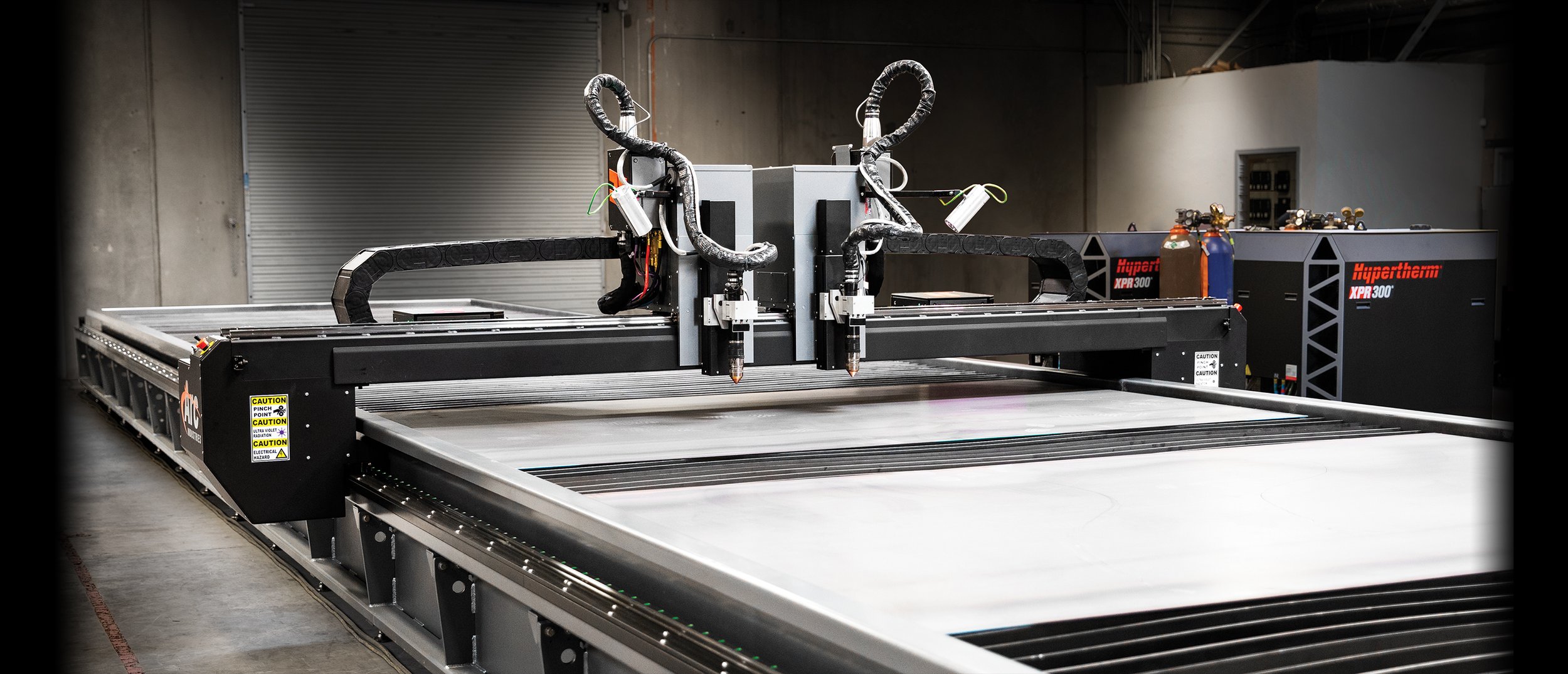

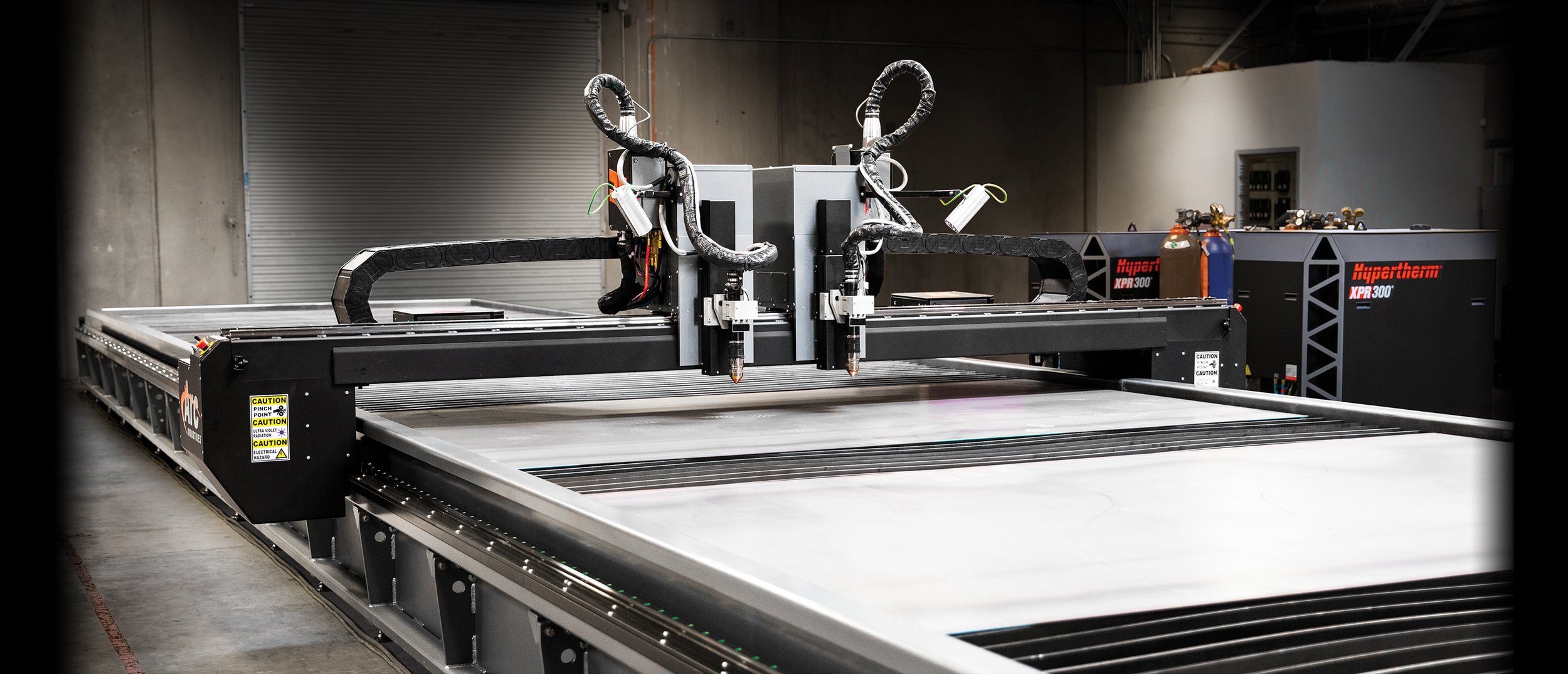

Arc Cutting Industries

Arc Cutting Industries machines combine an advanced controller with an industrial quality platform to meet the toughest demands of steel shops across the country. They offer water and downdraft table options as well as custom table sizes. Optional add-on features and capabilities are what set Arc Cutting Industries apart from the rest. Arc is proud to say that the Arc Cut Pro is designed and manufactured in the U.S.A.

Arc Cut Pro

Take your shop's production to the next level with an Arc Cut Pro Plasma Cutting Machine. The Arc Cut Pro's is built for high speed cutting while maintaining part accuracy and precision. Cut mild steel, stainless and aluminum with unmatched cut quality when combining the Arc Cut Pro with the most advanced plasma systems available: the Hypertherm XPR300 and XPR170.

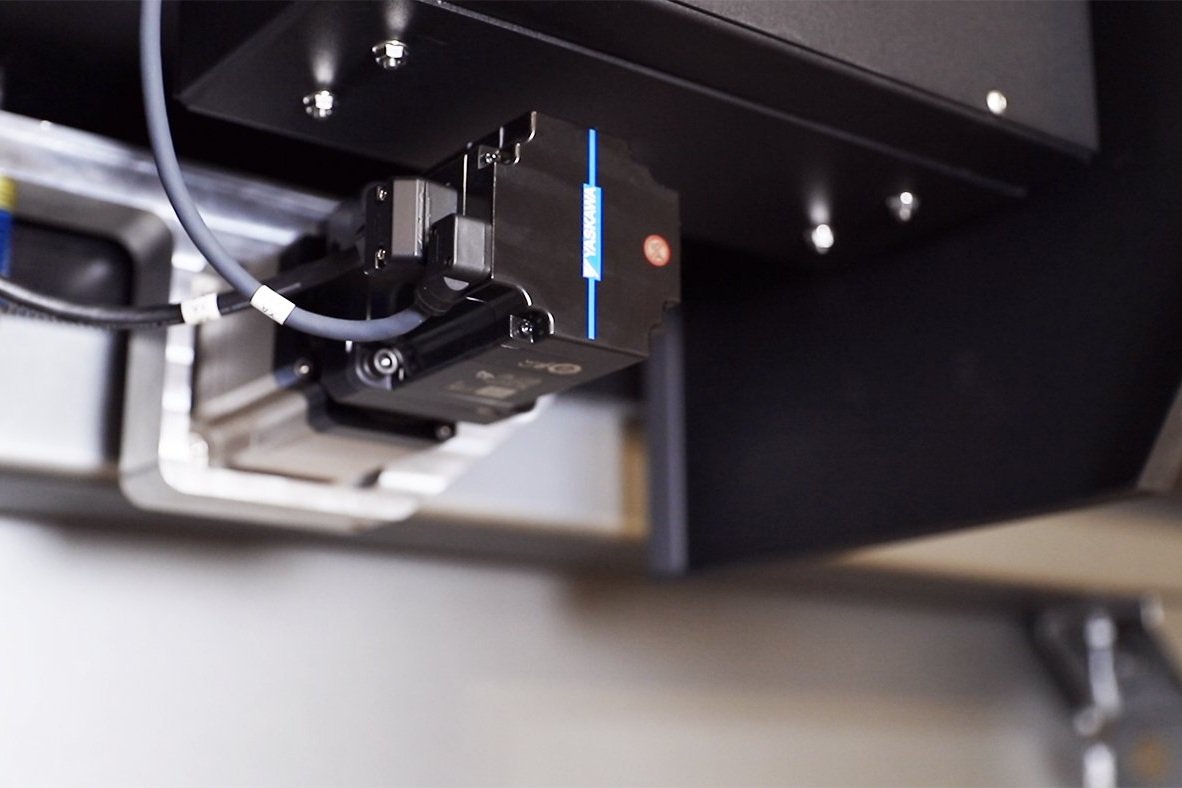

AUTOMATIC PLATE SKEWING

Automatic Plate Skewing will align the machine with skewed plate or structural material to increase efficiency and minimize wasted material.

PRECISION LIFTER

The laser system also allows the precision lifter to automatically compensate for any height changes or debris on the material creating superior cut quality.

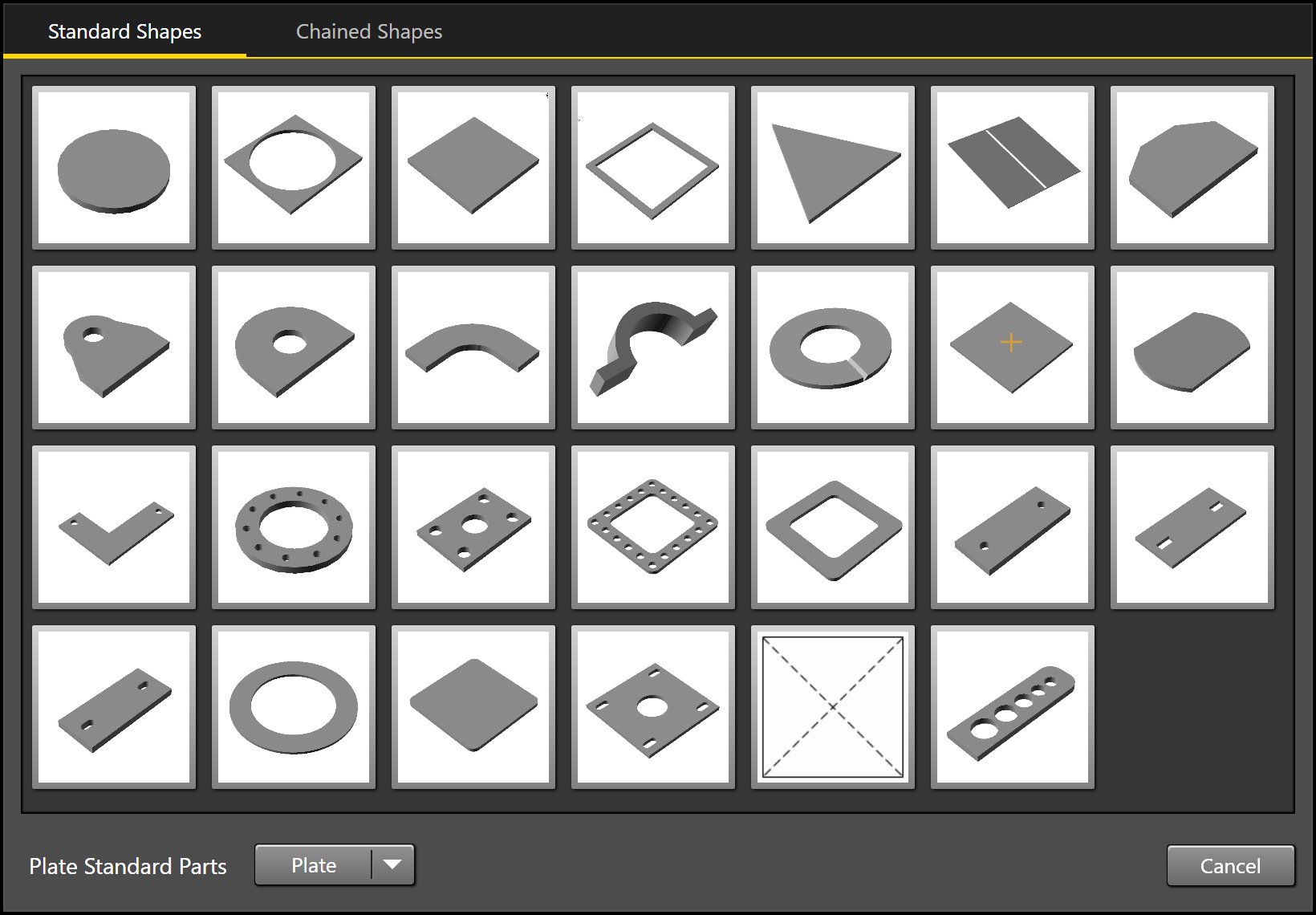

STRUCTURAL PROCESSING

Structural processing on a burn table is now a possibility using our Plate Mapping Technology. Import and process structural parts such as angle, channel, beams and tubing.

High Quality Servo Motors

The Arc Cut Pro Machine utilizes Yaskawa's Sigma-7 Servo Motors for extremely high quality production on an industrial grade level. Precision cutting with vibration suppression allow for smoother and more accurate parts at impressive speeds.

Advanced Plate Mapping

Using it's built-in Laser System, the Arc Cut Pro utilizes Advanced Plate Mapping technology to find the exact position and height of the material allowing for greater precision, higher efficiency and more versatility. Our Plate Mapping Technology is a key component in unlocking the full potential of the Arc Cut Pro Machine.

LIVE CAMERA VIEW

The Arc Cut Pro's built-in camera is contained in an industrial grade housing. The live camera view allows for easier torch alignment and live cut monitoring from the operator's controller.

CRASH DETECTION SYSTEM

Equipped with a magnetic mount crash detection system, the Arc Cut Pro automatically shuts down in the case of a collision to protect the plasma torch and the machine from damage.

INDUSTRY-CHANGING CONTROLLER

The Arc Cut Pro's Machine System Software comes with all the tools you need to get the most out of every run including the ability to nest on the controller. With an interactive 3D view that's uniquely designed for each specific machine, you can view cutting progress in real-time.

3D GRAPHICAL INTERFACE

The Arc Cut Pro Controller's machine software contains a detailed 3D graphical interface for viewing the machine and nest status in real-time. Set up saved locations and home points, jog cut paths, jump to certain parts or manually complete parts from the controller software. In addition to our 3D Machine View, the Steel Solutions Nesting Software allows you to view parts in 2D and 3D to view further details and help ensure proper part accuracy.

Hypertherm

Hypertherm is a world leader in plasma cutting technology, equipping the PCR lineup with high-definition plasma and true hole capabilities.

XPR300 represents Hypertherm’s most significant advance in mechanized plasma cutting technology ever and it's now available in multi-torch configurations.

Increases cut speed

Triples consumable life in many applications

Slashes operating costs by over 50%

Dramatically improves productivity